GM’s 3-speed manual transmissions‚ like the Saginaw‚ were pivotal in automotive history‚ offering reliable shifting and diverse applications across Chevrolet and Pontiac vehicles.

Historical Context of GM Manual Transmissions

GM’s journey with manual transmissions began in the early 20th century‚ evolving alongside automotive technology. Initially‚ these transmissions lacked synchronization‚ demanding skilled drivers. The introduction of synchronized gears‚ notably in models like the Muncie‚ significantly improved ease of use.

The Saginaw 3-speed emerged as a robust and widely-used option‚ particularly during the muscle car era. These transmissions were integral to vehicles from the 1950s through the 1980s‚ offering a balance of durability and affordability. GM continually refined these designs‚ adapting to changing vehicle needs and driver expectations.

Overview of the 3-Speed Saginaw Transmission

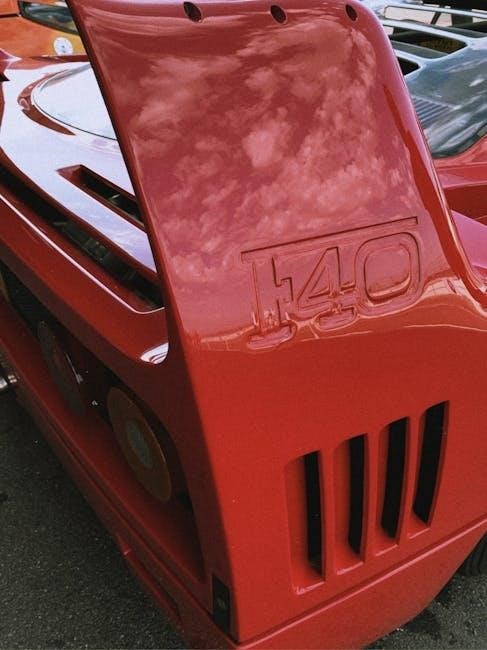

The Saginaw 3-speed manual transmission is renowned for its durability and widespread use in GM vehicles from the mid-1960s through the 1980s. Characterized by its simple design and robust construction‚ it proved reliable in a variety of applications. Identifying features include a generally round case and a 4-bolt side cover in many iterations.

It offered a straightforward three forward gears and reverse‚ providing a practical and cost-effective solution for many vehicles. The Saginaw’s internal components were designed for longevity‚ making it a favorite among enthusiasts for restorations and upgrades.

Identifying Your GM 3-Speed Transmission

Proper identification relies on examining case markings‚ source codes‚ and VIN codes stamped on the transmission housing‚ alongside physical features like the side cover’s bolt pattern.

Decoding the Transmission Case Markings

GM 3-speed transmissions feature crucial markings on the case‚ aiding identification. The source code‚ a numerical identifier‚ reveals the assembly plant and date of manufacture. Alongside it‚ a partial Vehicle Identification Number (VIN) provides the originating vehicle’s assembly details. These codes‚ often stamped prominently‚ are essential for accurate dating and model verification.

For example‚ Saginaw transmissions display specific codes. Understanding these markings allows enthusiasts to trace a transmission’s history and confirm its original application. Websites dedicated to GM transmissions offer comprehensive decoding guides‚ translating these numbers into valuable information about the unit’s origins and specifications.

Understanding Source Codes and VIN Codes

GM transmission source codes pinpoint the assembly plant and production date. A Saginaw’s code reveals where and when it was built‚ crucial for restoration projects. The partial VIN code links the transmission to the vehicle it originally equipped‚ confirming compatibility. Decoding these requires referencing specific charts for each GM division and year.

These codes aren’t interchangeable; a Chevrolet code differs from a Pontiac one. Online resources and dedicated forums provide detailed decoding guides. Correctly interpreting these markings ensures accurate parts sourcing and maintains originality during a rebuild or restoration‚ preserving the transmission’s historical integrity.

Identifying Features: 4-Bolt vs. Other Side Covers

The 4-bolt side cover is a key identifier for early GM 3-speed transmissions‚ specifically the Muncie non-synchro models found in 1955-1965 Chevrolet vehicles. This design differs significantly from later Saginaw transmissions with different bolt patterns. Curved bottom side covers‚ often with 9 bolts‚ indicate other variations.

Examining the gear selection shafts – round versus splined – further clarifies identification. The presence of a four-bolt cover doesn’t automatically confirm a Muncie; cross-referencing with the transmission case markings and source codes is essential for accurate determination. These visual cues aid in proper parts selection during restoration.

Key Components of the GM 3-Speed

GM 3-speed transmissions feature input/output shafts‚ synchronizers for smooth gear changes‚ and carefully chosen gear ratios impacting vehicle performance and overall driving experience.

Gear Ratios and Their Impact

GM’s 3-speed Saginaw transmissions utilized various gear ratios to optimize performance for different vehicles and driving conditions. These ratios directly influence acceleration‚ top speed‚ and fuel efficiency. Lower (numerically higher) ratios provide quicker acceleration but lower top speeds‚ ideal for heavy-duty applications or off-road use. Conversely‚ higher (numerically lower) ratios enhance fuel economy and allow for higher top speeds‚ suitable for highway cruising.

Identifying the specific gear ratio within a Saginaw transmission often involves examining the input and output shaft gear teeth counts or locating specific markings on the transmission case. Understanding these ratios is crucial for matching the transmission to the engine and intended vehicle use‚ ensuring optimal performance and drivability.

Input and Output Shafts

The GM 3-speed manual transmission’s input shaft transmits engine power to the gearbox‚ while the output shaft delivers power to the driveshaft and ultimately‚ the wheels. These shafts are critical components‚ designed to withstand significant torsional stress. Input shaft spline counts vary depending on the engine and clutch configuration. Output shaft variations exist to accommodate different vehicle rear-end ratios and flange styles.

Inspection of these shafts during a rebuild should focus on wear‚ damage to the splines‚ and bearing journal surfaces. Replacing worn shafts is essential for maintaining transmission reliability and preventing premature failure. Proper lubrication is also vital for shaft longevity.

Synchronizers and Their Function

GM 3-speed manual transmissions‚ particularly the Saginaw‚ utilize synchronizers to match the speeds of the gears before engagement‚ enabling smooth shifting. These components employ friction cones and blocking rings to equalize rotational velocities. Worn synchronizers cause grinding during shifts‚ indicating a need for replacement during a rebuild.

Proper synchronizer function relies on sufficient lubrication and intact friction surfaces. Inspecting the cones for wear and the blocking rings for damage is crucial. Replacing the entire synchronizer assembly is often recommended to ensure optimal performance and eliminate shifting issues.

Common GM 3-Speed Models

GM offered several 3-speed manuals‚ including the Muncie (non-synchro)‚ Saginaw‚ and early Borg-Warner T-10‚ each with unique characteristics and applications.

Muncie 3-Speed (Non-Synchro)

The Muncie 3-speed‚ particularly prevalent in 1955-1965 Chevrolet vehicles‚ represents an earlier transmission design lacking synchronizers on first and second gears. This necessitates a more skilled driving technique‚ demanding precise engine speed matching during downshifts to avoid grinding. Identifying a Muncie involves looking for a four-bolt side cover with round gear selection shafts. These transmissions were robust but required a deliberate shifting style. They are often found in classic car restorations‚ valued for their authenticity and simplicity‚ though modern drivers may find them challenging compared to synchronized counterparts.

Saginaw 3-Speed

The Saginaw 3-speed transmission became a common replacement for the Muncie‚ offering improved ease of use with partial synchronization. Identifying a Saginaw involves examining the transmission case markings – source and VIN codes provide crucial details. Various gear ratios were available‚ influencing vehicle performance. Input shaft grooves are typically cut across the clutch. Saginaw transmissions were widely used in numerous GM vehicles‚ offering a balance of durability and affordability. They represent a step forward in manual transmission technology‚ bridging the gap between older‚ fully non-synchronized designs and later‚ fully synchronized units.

Borg-Warner T-10 (Early Models)

Early Borg-Warner T-10 3-speed manual transmissions represent a significant piece of automotive history‚ predating widespread Saginaw adoption. These transmissions‚ often found in 1955-1965 Chevys‚ are identifiable by their distinctive four-bolt side covers and round gear selection shafts. They were initially non-synchronized‚ demanding skilled driving. The “AS-3” designation often appears on these units. Understanding the source code and partial VIN is crucial for accurate identification. While less common than later models‚ the T-10 laid groundwork for future transmission designs‚ offering a robust and reliable solution for performance applications.

Troubleshooting Common Issues

Common problems with GM 3-speeds include grinding gears‚ shifting difficulties‚ and unusual noises; diagnosis often involves inspecting synchronizers and checking gear alignment.

Grinding Gears

Grinding gears in a GM 3-speed often indicates worn synchronizers‚ the components responsible for matching gear speeds during shifts. This issue commonly presents when attempting to engage a specific gear‚ particularly second or third. Insufficient clutch engagement or a misadjusted clutch can exacerbate the problem‚ preventing complete gear separation. Inspecting the synchronizer rings and keys for wear is crucial. Additionally‚ low transmission fluid levels or contaminated fluid can contribute to grinding. Thoroughly examine the gear teeth for damage‚ as chipped or worn teeth will also cause grinding noises and difficulty shifting smoothly.

Difficulty Shifting

Difficulty shifting in a GM 3-speed manual transmission can stem from several sources‚ often linked to the linkage or internal components. A worn or improperly adjusted shift linkage is a frequent culprit‚ preventing full engagement of the shift forks. Internal issues include worn shift keys‚ damaged synchronizers‚ or bent shift forks. Low or contaminated transmission fluid can also hinder smooth operation. Inspect the clutch for proper disengagement‚ as a dragging clutch will make shifting challenging. Thoroughly check the floor shift mechanism for looseness or binding‚ ensuring proper movement.

Transmission Noise

Transmission noise in a GM 3-speed manual can indicate various problems‚ ranging from minor to severe. Whining sounds often point to worn bearings within the transmission‚ particularly the input or output shaft bearings. Grinding noises‚ especially during gear changes‚ suggest damaged synchronizers or worn gear teeth. A clunking sound might indicate excessive backlash in the gears or a loose universal joint. Regularly check the fluid level; low fluid can exacerbate noises. Identifying the type of noise and when it occurs is crucial for accurate diagnosis and repair.

Rebuilding a GM 3-Speed Transmission

Rebuilding involves careful disassembly‚ thorough inspection of all components‚ replacing worn parts like synchronizers and bearings‚ and precise reassembly with proper adjustments.

Disassembly and Inspection

Disassembly requires methodical removal of components‚ documenting their location for reassembly. Begin by draining the fluid‚ then separating the transmission from the bellhousing. Carefully remove the tailshaft housing‚ shift forks‚ and gears‚ noting their orientation.

Inspection is crucial; examine gears for wear‚ chips‚ or cracks. Check synchronizers for proper function and wear on the blocking rings. Inspect bearings and shafts for damage. Look closely at the case for cracks or stripped threads. Any damaged parts must be replaced to ensure a reliable rebuild‚ preventing future failures.

Parts Replacement

Parts replacement during a GM 3-speed rebuild necessitates quality components. Worn gears‚ synchronizers‚ bearings‚ and seals should always be replaced. Consider a new clutch disc‚ pressure plate‚ and throwout bearing for a complete overhaul. Inspect and replace any damaged shift forks or linkage components.

Utilize a reputable supplier for accurate parts; incorrect components can lead to shifting issues. Ensure proper lubrication during reassembly with transmission-specific fluid. Replacing all wearable parts guarantees longevity and smooth operation‚ restoring the transmission to its original performance.

Reassembly and Adjustment

Reassembly requires meticulous attention to detail‚ following a reverse order of disassembly. Proper bearing preload and gear mesh are crucial for quiet operation and longevity. Carefully install synchronizers‚ ensuring correct orientation and spring tension. Adjust shift linkage for precise engagement‚ eliminating binding or looseness.

Verify input and output shaft endplay within specifications. Use a torque wrench to tighten all fasteners to the manufacturer’s recommended values. Finally‚ fill the transmission with the correct fluid and check for leaks before installation‚ guaranteeing smooth shifting.

Applications and Vehicle Compatibility

GM 3-speed manuals found widespread use in Chevrolet‚ Pontiac‚ and other GM vehicles from the 1950s through the 1980s‚ offering versatile performance.

Chevrolet Applications

Chevrolet extensively utilized the GM 3-speed manual transmissions across numerous models‚ particularly during the mid-20th century. Early applications included the iconic 1955-1965 Chevrolet cars‚ where the Muncie non-synchro 3-speed was common‚ identifiable by its four-bolt side cover. Later models‚ like certain Camaros and Novas‚ often featured the Saginaw 3-speed. These transmissions provided a durable and cost-effective solution for a wide range of Chevrolet vehicles‚ from full-size sedans to sporty muscle cars. Identifying the specific transmission within a Chevrolet often requires decoding the case markings and source codes.

Pontiac Applications

Pontiac also frequently incorporated GM’s 3-speed manual transmissions into their vehicle lineups‚ mirroring Chevrolet’s adoption. Models like the early Pontiac Tempest and LeMans often utilized the Saginaw 3-speed‚ providing a reliable and affordable manual transmission option. Similar to Chevrolet‚ identifying the specific Pontiac transmission requires careful examination of the case markings‚ including the source code and partial VIN. These transmissions were crucial for offering a manual driving experience in Pontiac’s diverse range of cars‚ contributing to their popularity and performance.

Other GM Vehicle Applications

Beyond Chevrolet and Pontiac‚ GM’s 3-speed manual transmissions found their way into various other divisions. Buick and Oldsmobile‚ while often associated with automatic transmissions‚ also utilized these manuals in select models‚ particularly during the mid-20th century. Identifying these applications relies heavily on decoding the transmission case markings – the source code and partial VIN are key. These transmissions provided a cost-effective and durable manual option‚ broadening GM’s vehicle offerings and catering to a wider range of customer preferences across its brands.

GM vs. Other Manual Transmissions

Compared to 4-speed and modern manuals‚ GM’s 3-speed offered simplicity and durability‚ though lacked the advanced ratios for optimal performance and fuel economy.

Comparison to 4-Speed Manuals

GM’s 3-speed transmissions‚ while robust‚ generally offered fewer gear ratios than their 4-speed counterparts‚ like the popular Muncie M21 and M22. This difference impacted performance; 4-speeds provided closer ratios‚ allowing engines to stay within their optimal power band more consistently. Consequently‚ 4-speeds often resulted in quicker acceleration and improved highway cruising.

The 3-speed’s simplicity‚ however‚ made it more durable and easier to rebuild. While 4-speeds offered a more refined driving experience‚ the 3-speed remained a cost-effective and reliable option for many applications‚ particularly in earlier muscle cars and trucks where outright speed wasn’t the sole priority.

Comparison to Modern Manual Transmissions

Compared to modern manual transmissions‚ GM’s 3-speeds represent a significant technological leap backward. Contemporary manuals often feature 5‚ 6‚ or even 7 speeds‚ offering vastly improved fuel efficiency and performance through wider gear ratio spreads. Modern transmissions also incorporate features like overdrive‚ computer controls‚ and lighter materials for smoother shifting and reduced weight.

The 3-speed’s lack of synchronization on first gear in some models‚ and its generally clunkier operation‚ contrasts sharply with the refinement of modern designs. While lacking sophistication‚ the 3-speed’s simplicity provides a direct‚ mechanical feel absent in many modern‚ electronically-assisted systems.

Resources for GM 3-Speed Information

Online forums and dedicated communities provide valuable insights‚ while parts suppliers offer components for restoration. Technical manuals detail specifications and procedures for GM’s 3-speed.

Online Forums and Communities

Numerous online forums are dedicated to classic GM vehicles‚ offering a wealth of knowledge regarding the 3-speed manual transmissions. These platforms connect enthusiasts who share experiences‚ troubleshooting tips‚ and restoration advice. Websites dedicated to specific models‚ like Camaros and Novas‚ often have active transmission sections.

Members frequently discuss identifying transmission codes‚ sourcing parts‚ and performing rebuilds. These communities are invaluable for diagnosing issues‚ understanding quirks‚ and finding rare components. Participating in these forums allows owners to tap into collective expertise and avoid common pitfalls during restoration or repair projects‚ fostering a collaborative learning environment.

Parts Suppliers

Sourcing parts for GM 3-speed manual transmissions requires exploring specialized suppliers catering to classic car restoration. Several companies focus on vintage transmission components‚ offering rebuilt units‚ individual parts like gears and synchronizers‚ and complete rebuild kits. Online retailers specializing in classic Chevrolet and Pontiac parts are also valuable resources.

Local auto parts stores may carry some universal components‚ but specific 3-speed parts often necessitate ordering from dedicated suppliers. When purchasing‚ verifying compatibility with your transmission’s specific model and year is crucial to ensure a proper fit and function‚ avoiding costly errors during the rebuild process.

Technical Manuals and Documentation

Accessing original GM technical manuals is invaluable for rebuilding a 3-speed manual transmission. These manuals provide detailed exploded views‚ torque specifications‚ and step-by-step disassembly/assembly instructions. Factory service manuals specific to the vehicle your transmission came in often contain relevant sections. Online forums and enthusiast communities frequently archive scanned copies of these manuals.

Supplementing factory manuals with aftermarket rebuild guides can offer additional insights and troubleshooting tips. Digital documentation‚ including parts catalogs and diagrams‚ simplifies identifying components and understanding their function‚ ensuring a successful and accurate restoration.